Airquest HVAC Trainings

📢 Don’t see the HVAC training you need?

Join our waiting list below to be notified about upcoming sessions, including government rebate programs and new HVAC training opportunities!

Who Should Attend?

HVAC Contractors, Technicians, and Installers looking to enhance their knowledge of Airquest ducted central heat pumps.

🎓 Certificate of Attendance Included!

Attendees will receive an official Certificate of Attendance, beneficial for rebate program applications and professional development.

🚀 What You’ll Learn:

✅ System features & installation best practices

✅ Key insights for HVAC professionals

✅ Live Q&A with industry experts

🔔 Limited Spots – First Come, First Served!

- Registrants will be contacted to confirm their spot.

- If spots are filled, additional registrations will be placed on a waiting list.

615 Bowes Road, Unit #8, Concord, Ontario, L4K 1J5, Canada

Airquest Brand Reliability

Airquest is a brand of high-quality heating and cooling products that is backed by the leading HVAC manufacturer, Carrier. Being backed by a world-class company solidifies our reputation for quality and reliability and provides us with the latest in product innovations for home comfort solutions.

Relentless Testing

We are obsessed with testing our products, so much that we go well-beyond testing industry standards.

We are relentless in our pursuit to deliver reliable, high-quality products. To prove it, we run test every single unit before it leaves the factory and perform the following tests.

Psychrometric Room Testing

In our psychrometric room, we transition from 20 degrees below zero to extreme heat over 120 degrees in order to thermally shock air conditioners and heat pumps and see if they are still able to heat and cool properly.

Furnace Testing

In our furnace and component test laboratory, we run furnaces and fans non-stop to simulate over 20 years of use in a single year, which is over 6x the industry standards. At our furnace test stations, we install furnaces in every orientation: upflow, downflow, or horizontally to ensure they are properly installed for high performance.

Electronic Components Testing

Our electronic components have their own area. The Highly Accelerated Life Testing, or HALT chamber. In it, we subject these components to current and voltage spikes, 390 degree heat, and vibration at 80 times the acceleration of gravity.

Salt Air Chamber

Our salt air chamber ensures systems installed in coastal areas can withstand the naturally corrosive effects of the sea.

Acid Building

We maintain a high humidity environment and use acid to speed up the effects of natural corrosion on coils and other metal parts.

Sound Room Chamber

We even test things you can’t see, using quiet rooms, sound studios, and field testing, we monitor sound output so we can devise new ways of reducing volume levels. We also use sound testing to identify distracting sounds for us to eliminate.

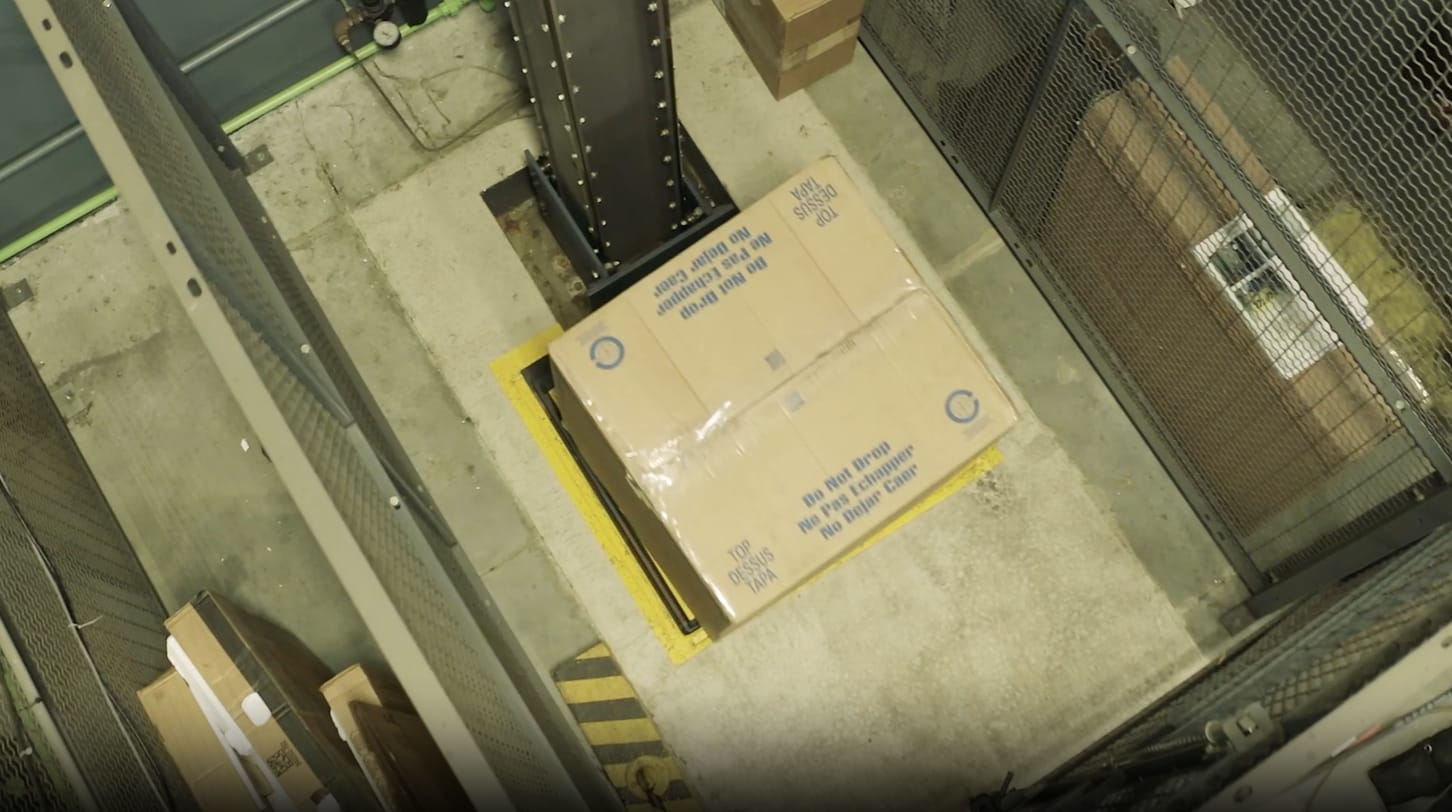

Shaker Table

We’re able to design systems that can handle the wear and tear of the journey from the factory to their new home through three different tests. Our shaker table simulates the vibrations in the back of a truck.

Impact Tester

Our impact tester mimics small collisions that may happen during shipping.

Drop Tester

Our drop tester which measures the survivability of drops during loading and unloading.