But what exactly is VRF, and why is the commercial market moving in this direction? In this post, we’ll break down how VRF systems work, the benefits they offer, and how brands like Airquest—a proud member of the Carrier family—are leading this shift with high-performance, flexible systems designed for North American climates.

What Is a VRF System?

VRF stands for Variable Refrigerant Flow. It’s an advanced HVAC technology that uses refrigerant as the heating and cooling medium. Unlike conventional systems, where the refrigerant flow is fixed or limited, VRF systems modulate the amount of refrigerant sent to each indoor unit based on the space’s needs.

This modulation allows each zone in a building to be independently controlled, making it highly efficient and flexible. VRF systems are a type of multi-split system, meaning a single outdoor unit can serve multiple indoor units—sometimes up to 64.

There are two main types of VRF systems:

- Heat Pump VRF: Can either heat or cool at a time across all zones.

- Heat Recovery VRF: Can heat in some zones while cooling others simultaneously—ideal for mixed-use buildings.

How Does a VRF System Work?

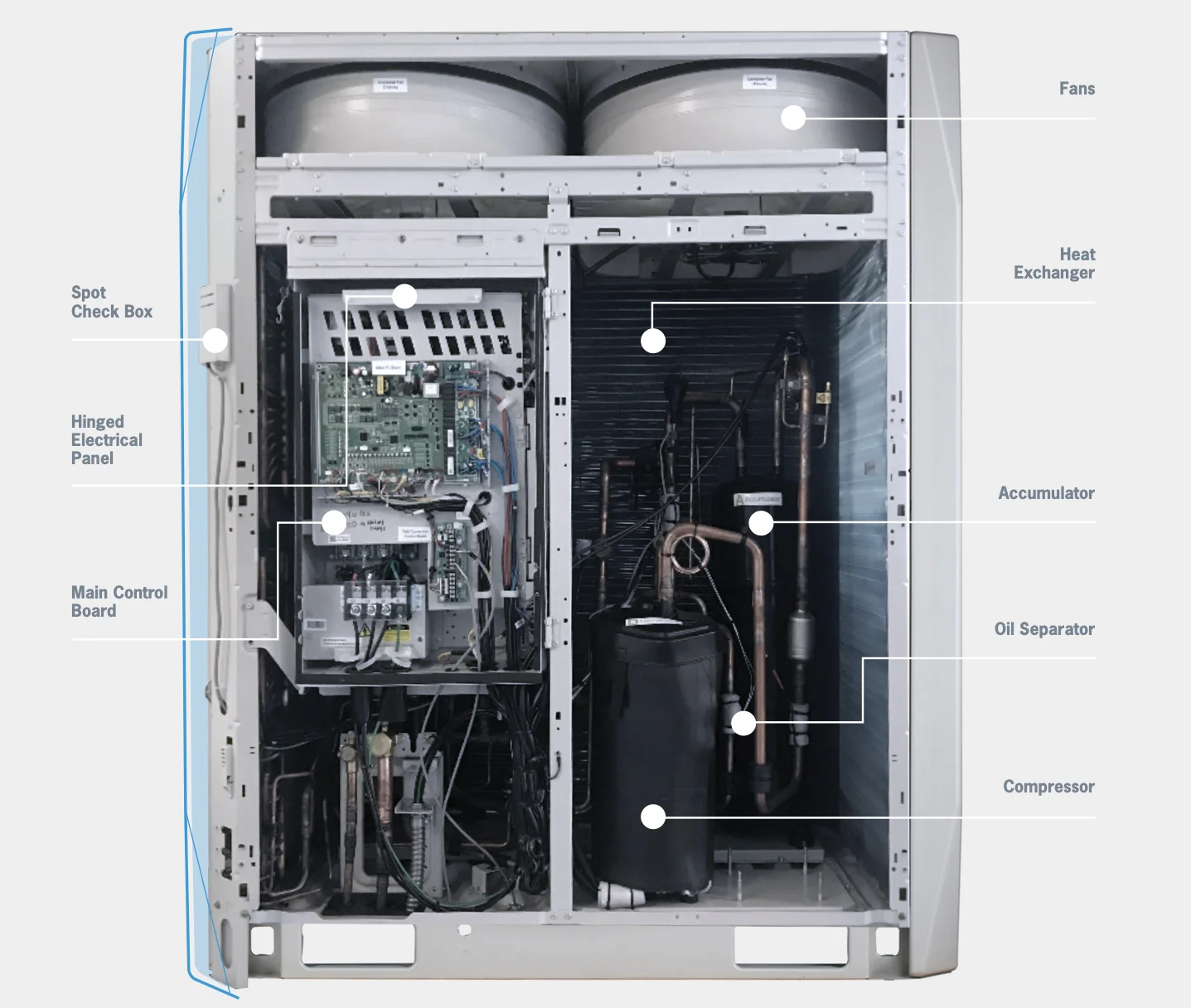

The heart of the system is the inverter-driven compressor in the outdoor unit. Instead of switching on and off repeatedly like traditional HVAC compressors, it adjusts its speed continuously. This variable speed determines how much refrigerant is delivered to each indoor unit.

Each indoor unit measures the temperature of its zone and signals the outdoor unit to increase or decrease refrigerant flow. The system calculates demand in real-time and responds accordingly. This not only increases energy efficiency but also extends system lifespan.

In heat recovery systems, the VRF setup includes multiport distribution controllers (MDCs). These components allow the system to extract heat from one part of the building and reuse it in another. For example, excess heat from a sunny office can warm a shaded conference room—all within the same system.

Why Is VRF Becoming Popular in Commercial Applications?

There are several key reasons behind the shift toward VRF technology in commercial projects:

1. Zoned Comfort with Full Control

Each indoor unit operates independently. This means conference rooms, hotel suites, classrooms, and lobbies can all be set to different temperatures based on occupancy or usage. Facility managers can fine-tune comfort while reducing energy waste.

2. High Efficiency, Lower Operating Costs

VRF systems reduce energy consumption by only delivering what’s needed to each zone. There’s no need to move air through long duct runs or overwork a central system. Technologies like asymmetric scroll compressors and electronic expansion valves further optimize performance.

Airquest VRF units, for example, deliver excellent Integrated Energy Efficiency Ratios (IEER), helping many buildings qualify for LEED or other green building certifications.

3. Simultaneous Heating and Cooling

One of the biggest advantages of heat recovery VRF systems is the ability to heat and cool at the same time. This is a game-changer for buildings with mixed usage throughout the day—like hotels, offices, or senior living facilities. You can cool a data room while heating a lounge, all with one integrated system.

4. Flexible Design and Installation

VRF systems don’t require large ducts or mechanical rooms. This means designers can reclaim valuable square footage for usable space. With compact outdoor units and soft copper piping, VRF systems are also easier to install in tight spaces or retrofits.

Airquest VRF systems support piping lengths up to 3,280 feet and elevation changes up to 164 feet—ideal for mid- and high-rise buildings.

5. Quiet Operation

With indoor sound levels as low as 58.4 dB(A), VRF systems are significantly quieter than many rooftop units or central air systems. This is especially important in hotels, schools, and offices where a peaceful environment matters.

6. Smart Controls and Integration

VRF systems are built for modern buildings. With central control panels and integration into building automation systems like Carrier’s i-Vu®, facility managers get a 360-degree view of their system performance, energy use, and zone-level conditions.

7. Scalable for Growth

Need to expand later? No problem. VRF systems are modular. You can add new indoor units or upgrade sections without replacing the entire system. This is ideal for phased construction projects or buildings undergoing renovations.

Is VRF Right for Every Project?

Not necessarily. While VRF systems offer incredible benefits, they also come with a higher upfront cost and require trained technicians for proper installation. However, with support from experienced distributors like Nordics, who provide full technical support, design guidance, and product availability, many of those concerns are minimized.

At Nordics, we supply Airquest VRF systems across Ontario and beyond. These systems are built specifically for North American conditions, with proven performance in both harsh winters and hot summers. With support from Carrier’s extensive engineering and technology resources, Airquest VRF solutions bring flexibility, comfort, and efficiency to a whole new level.

Final Thoughts

As buildings become smarter and energy efficiency regulations tighten, the demand for more advanced HVAC systems continues to grow. Variable Refrigerant Flow (VRF) systems are at the forefront of this movement—especially in commercial and multi-zone applications.

Whether you’re designing a hotel, retrofitting an office tower, or managing a mixed-use facility, VRF may be the right fit for your project. And with the backing of brands like Airquest, supported by the Carrier legacy, you can count on reliable performance and long-term value.

Looking to learn more about VRF systems or explore options for your next commercial build? Contact Nordics to get connected with our HVAC specialists today.